Hot Air Infrared Reflow SMD Workstation

1. Hot air infrared Reflow SMD workstation DH-A2 BGA rework station. 2. This reballing machine can function very well in desoldering, removing chips, reballing, soldering. 3. Super long lifespan. 4. Strictly control temperature.

Deskripsi

Automatic Hot air infrared Reflow SMD workstation

An automatic hot air infrared reflow SMD workstation is a type of equipment used to attach surface-mount

components (SMDs) onto printed circuit boards (PCBs). The workstation typically uses a combination of hot

air convection and infrared heating to heat the SMDs and solder paste, causing the solder to melt and secure-

ly attach the components to the PCB.

The automatic hot air infrared reflow SMD workstation typically includes features such as temperature profi-

ling, adjustable airflow control, and real-time temperature monitoring. These features ensure that the SMDs

are heated and cooled at a controlled rate, reducing the risk of thermal damage to the components and PCB.

Additionally, the computer-controlled precision allows for repeatable and reliable results, making the reflow

process efficient and consistent.

In summary, an automatic hot air infrared reflow SMD workstation is a valuable tool for electronics assembly

and repair, offering a quick and efficient way to attach SMDs to PCBs with minimal risk of damage.

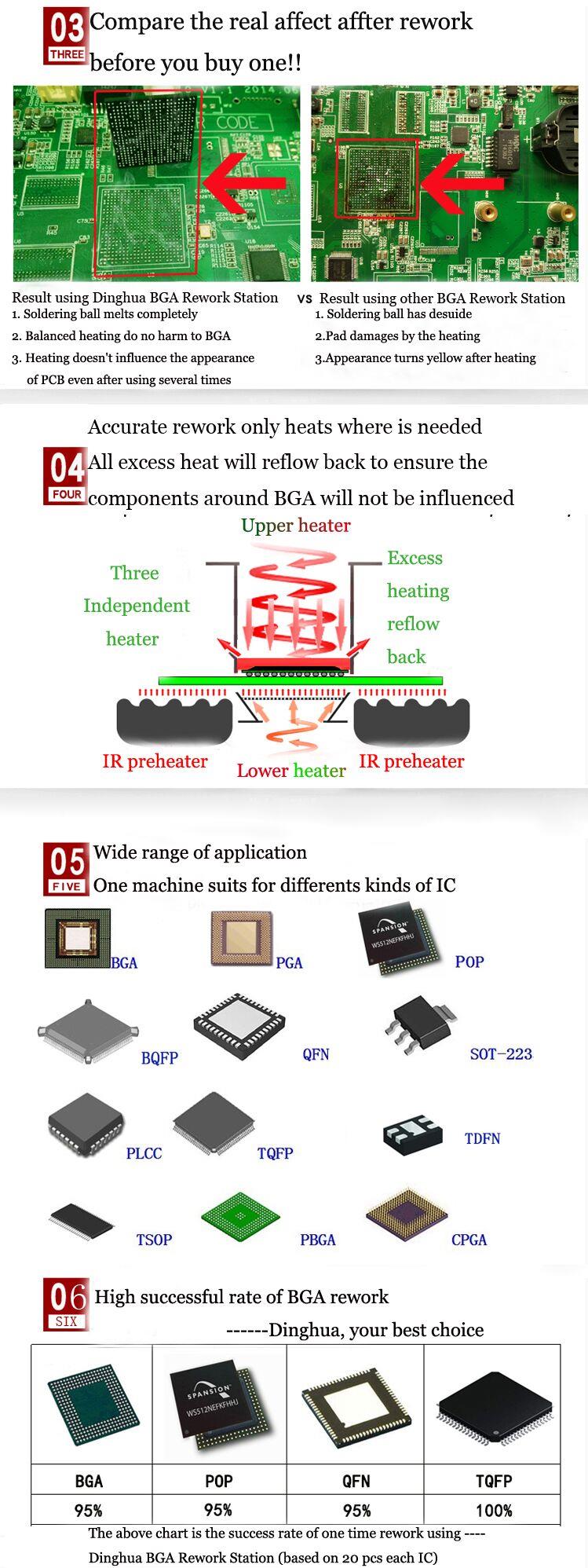

1.Application Of Automatic Hot air infrared Reflow SMD workstation

Work with all kinds of motherboards or PCBA.

Solder, reball, desoldering different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP,

PBGA,CPGA,LED chip.

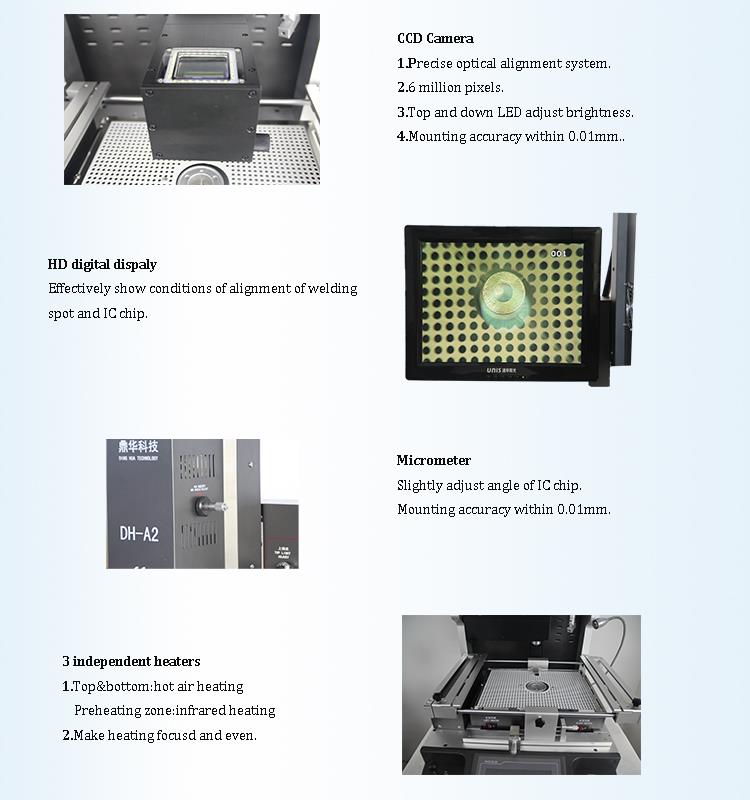

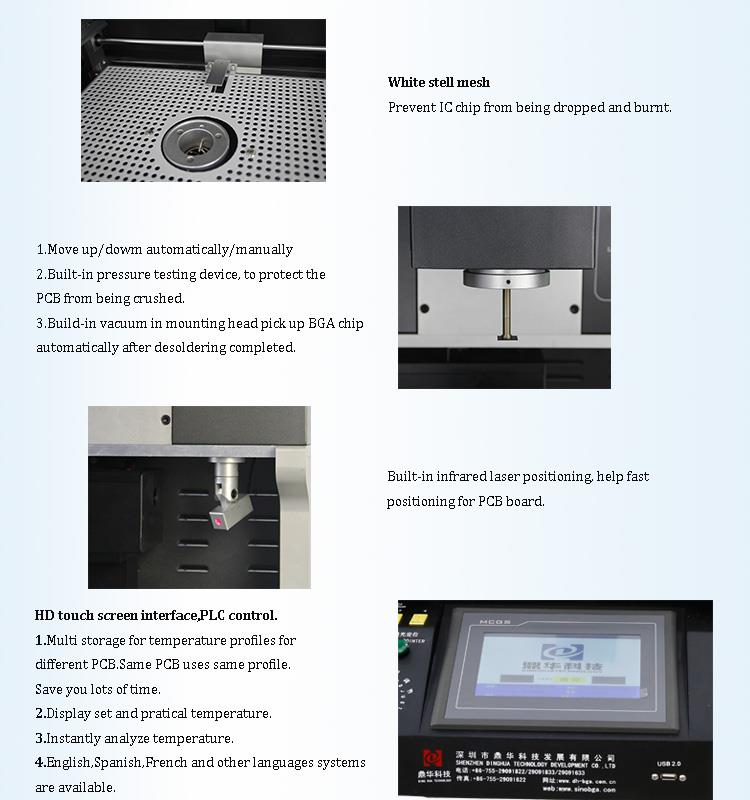

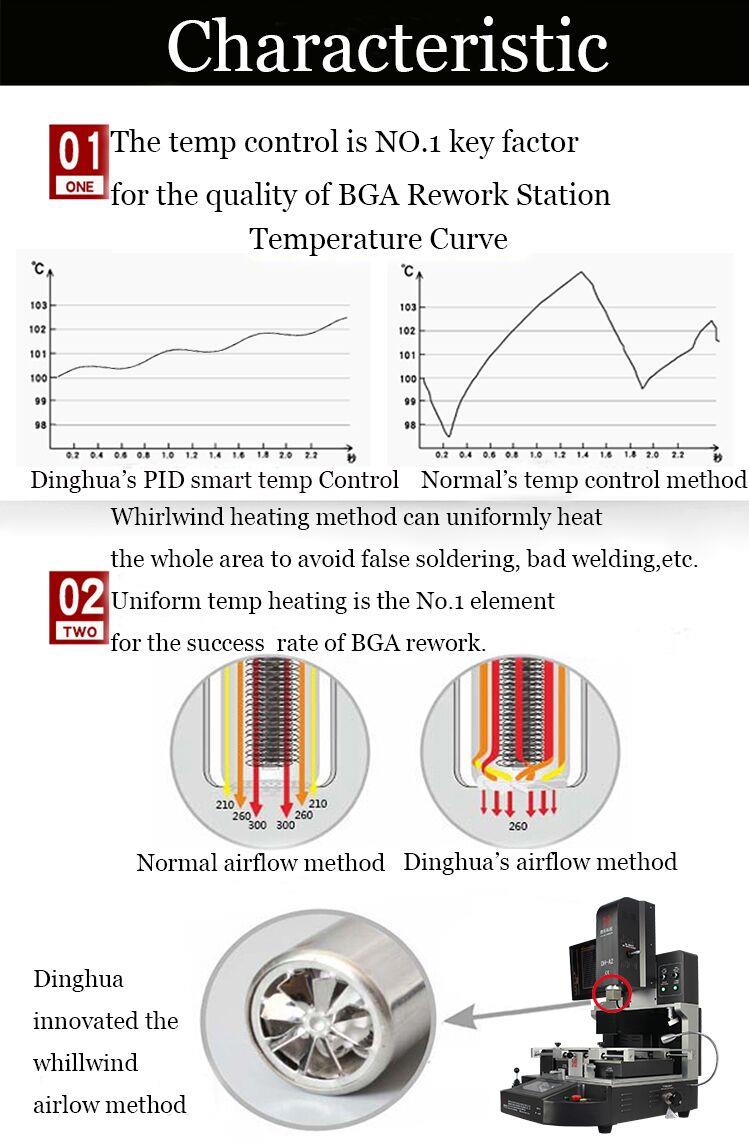

2.Product Features of Automatic Hot air infrared Reflow SMD workstation

3.Specification of Automatic Hot air infrared Reflow SMD workstation

4.Details of Automatic Hot air infrared Reflow SMD workstation

5.Why Choose Our Automatic Hot air infrared Reflow SMD workstation?

6.Certificate of Automatic Hot air infrared Reflow SMD workstation

UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system,

Dinghua has passed ISO, GMP, FCCA, C-TPAT on-site audit certification.

7.Packing & Shipment of Automatic Hot air infrared Reflow SMD workstation

8.Shipment for Automatic Hot air infrared Reflow SMD workstation

DHL/TNT/FEDEX. If you want other shipping term, please tell us. We will support you.

9. Terms of Payment

Bank transfer, Western Union, Credit Card.

Please tell us if you need other support.

10. How DH-A2 Semi Automatic Hot air infrared Reflow SMD workstation?

11. Related knowledge

PCBA proofing directly determines whether PCBA is mass-produced. The company has a dedicated PCBA proofing production line and builds it according

to international production standards. At the same time, it also sets up a new product introduction (NPI, New Product Introduction) engineer group, proc-

ess quality control team and The professional production team fully serves PCBA proofing production, and strives to meet the core needs of customers for

fast delivery and quality assurance.

PCBA proofing advantages

Fastest 7-day proofing

100% test of all PCBA board samples before leaving the factory

Support special processes such as single and double panel, 4-layer board, multi-layer board, HDI, impedance, blind buried hole, etc.

Rogers A+ military grade plate production, electronic components are from the original agent of the original agent, with strict IQC incoming inspection control

Equipped with a new top-class Samsung SMT patch production line, supporting the perfect placement of complex components such as 0201 and BGA

User first price discount, engineering fee reduction 20%-50%

Free documentation of DFM analysis and trial production analysis reports to provide a manufacturing reference for customer's document design

When Dinghua Electronics delivers PCBA samples, it not only ensures soldering reliability, but also provides PCBA board processing pictures and professional

design recommendations. Promoting PCBA proofing to an important position than volume orders is our philosophy of serving sample orders. Use samples to let

customers feel our professional service capabilities and build trust in cooperation. Nuo's electronics is the best choice for your PCBA proofing supplier!